|

|

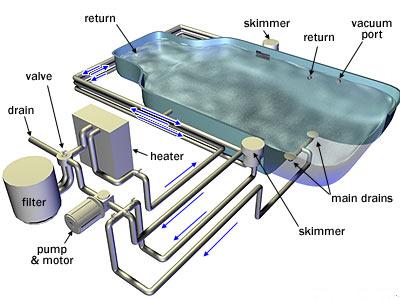

Inspect the Equipment Pad: Check the pump, motor, filter, valves, heater, chlorinator and backwash for leaks. Skimmers: Check the housings, gaskets, tiles & skimmer entrance bond Pipes: Isolate and test each pipe as permitted by existing valve and plumbing arrangement Underwater Inspection - Vinyl Liner Pool: Visually, tactually and with detection dye, stairs, ladders, inspect the liner for: leaks, pinholes, tears, seam defects, check all gaskets, faceplates and screws. Patch up to 20 holes, liners with over 20 holes may be charged extra. Insect,TERMITE, pinholes are common in above ground pool liners and may be patched or sealed with caulk. Underwater Inspection - Gunite or Fiberglass Pools: Visually, and with leak detection dye, inspect the surface of the pool shell for cracks and leaks, check every pipe fitting for leaks, check the tile border and entrances to the skimmers. Lights: Inspect and dye test the light conduit, ground fittings, gaskets, screws, and niches for leaks, cracks, or corroded metal. Hydrostatic Valves: Dye test hydro valves, test and evaluate valve function, clean seals, replace gaskets and / or replace entire valves. Main Drain Pipes, Sumps, Drain Safety Covers: Isolate and test the main drain pipe(s), check the sump for leaks, evaluate the main drain safety cover for function, properly secured, make recommendations for upgrading to VGB certified covers. As the underwater leaks are found and confirmed with leak detection dye, they are repaired with a variety of glues, solvents, epoxies, caulks, rubber sealants, patches, plaster or fiberglass. All repair materials are designed to be applied underwater. Swimming may resume after the repairs are completed. NO SWIMMERS MAY BE IN THE POOL DURING THE INSPECTION.

|

||||||||||||||||

Copyright © 2010, 2012